Sleeve

2019-04-20 09:32

Cnpow

Click:

The technical characteristics of the sleeve: 1. It is suitable for the reinforcement of various structures that can withstand the two-way force of tension and compression.

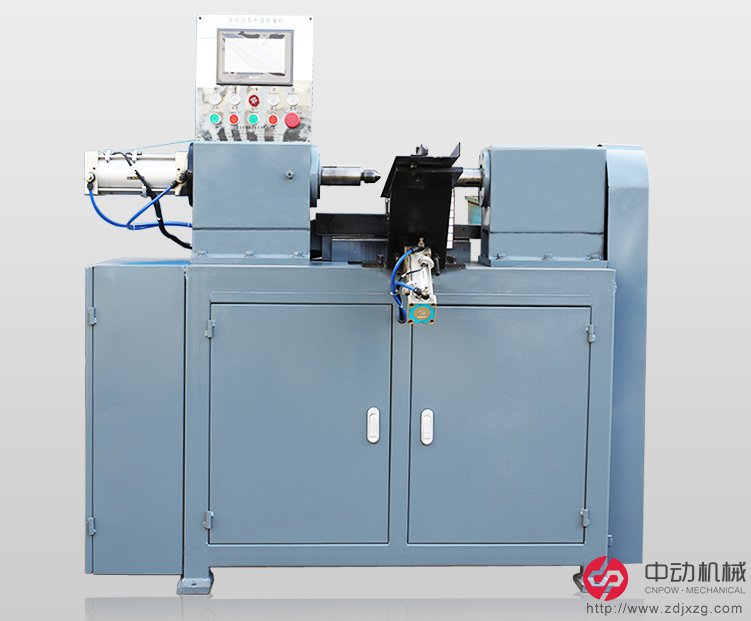

Steel sleeve cold extrusion joint technology

Steel sleeve cold extrusion joint technology

Construction of steel bars in the structure. 2, material, energy, not limited by the composition and type of steel. 3, can be connected in all directions. 4, can be pre-made in advance, factory operations, do not take up the construction period, all-weather construction. 5, easy to operate, fast, fast construction, can greatly shorten the construction period

Technical characteristics of the steel connecting sleeve The joint strength meets the performance requirements of the A-level joint in the industry standard JGJ107-96. The thread shape is good, the precision is high, and the connection quality is stable and reliable. Wide range of applications, suitable for diameters of 16-40mm. Class II and III steel bars are connected in the same direction and in different directions. Adjustable type: The positive and negative threaded sleeves are suitable for the connection of steel bars such as iron cages that cannot be rotated. Fast construction speed: pre-fabrication and on-site processing of thread processing, assembly and construction. Energy saving, no pollution, safe and reliable construction.

Socket wrench

Socket wrench: It is composed of a plurality of sleeves with hexagonal holes or twelve-corner holes and is equipped with various accessories such as handles and posts. It is especially suitable for turning bolts or nuts with very narrow position or deep depression. .

A socket wrench classification:

(1) by size (refers to the size of the square head): 1/4 〃, 3/8 〃, 1/2 〃 three specifications, 〃 is the meaning of inches, 1 〃 is equal to 25.4MM

(2) Length: long sleeve, short sleeve, E-shaped sleeve

Sleeve

Sleeve

(3) Press side: 6 angles, 12 angles

(4) Appearance: single groove and double groove; knurling; straight tube; nickel plating and networking

(5) Use: There are manual socket wrenches and pneumatic socket wrenches (black, chrome molybdenum steel)

Second surface treatment

(1) Bright chrome: like a mirror, very bright

(2) chrome: matt

(3) Electrophoresis: black, with brightness. Under the action of an external DC power source, the charged particles are moved toward the cathode or the anode in a dispersed medium to promote separation of substances;

(4) Phosphating: black, but dull. The sleeve is immersed in a phosphating solution and deposited on the surface to form a layer of water-insoluble crystalline phosphorus, which is a phosphate conversion process.

Three production process

Blanks (a variety of specifications) - sanding (removing burrs, etc.) - turning (mainly forming) - sanding the surface - engraving (such as knurling, printing LOGO, etc.) - heat treatment (in order to increase its hardness )--Electroplating (nickel or chrome, etc.)

Four distinctions between good and bad

(1) Look at the surface: Is there any burrs, whether the specifications meet the size standards, whether there are scratches, etc.

(2) Endoplasm: measuring torque and hardness with special tools; measuring size; salt spray test, etc.

Note: When the hexagonal or twelve-sided edge size of the socket wrench is less than or equal to 32MM, the hardness value is not lower than HRC39. When it is greater than 32MM, the hardness is not lower than HRC35.

Steel sleeve cold extrusion joint technology

Steel sleeve cold extrusion joint technology

Construction of steel bars in the structure. 2, material, energy, not limited by the composition and type of steel. 3, can be connected in all directions. 4, can be pre-made in advance, factory operations, do not take up the construction period, all-weather construction. 5, easy to operate, fast, fast construction, can greatly shorten the construction period

Technical characteristics of the steel connecting sleeve The joint strength meets the performance requirements of the A-level joint in the industry standard JGJ107-96. The thread shape is good, the precision is high, and the connection quality is stable and reliable. Wide range of applications, suitable for diameters of 16-40mm. Class II and III steel bars are connected in the same direction and in different directions. Adjustable type: The positive and negative threaded sleeves are suitable for the connection of steel bars such as iron cages that cannot be rotated. Fast construction speed: pre-fabrication and on-site processing of thread processing, assembly and construction. Energy saving, no pollution, safe and reliable construction.

Socket wrench

Socket wrench: It is composed of a plurality of sleeves with hexagonal holes or twelve-corner holes and is equipped with various accessories such as handles and posts. It is especially suitable for turning bolts or nuts with very narrow position or deep depression. .

A socket wrench classification:

(1) by size (refers to the size of the square head): 1/4 〃, 3/8 〃, 1/2 〃 three specifications, 〃 is the meaning of inches, 1 〃 is equal to 25.4MM

(2) Length: long sleeve, short sleeve, E-shaped sleeve

Sleeve

Sleeve

(3) Press side: 6 angles, 12 angles

(4) Appearance: single groove and double groove; knurling; straight tube; nickel plating and networking

(5) Use: There are manual socket wrenches and pneumatic socket wrenches (black, chrome molybdenum steel)

Second surface treatment

(1) Bright chrome: like a mirror, very bright

(2) chrome: matt

(3) Electrophoresis: black, with brightness. Under the action of an external DC power source, the charged particles are moved toward the cathode or the anode in a dispersed medium to promote separation of substances;

(4) Phosphating: black, but dull. The sleeve is immersed in a phosphating solution and deposited on the surface to form a layer of water-insoluble crystalline phosphorus, which is a phosphate conversion process.

Three production process

Blanks (a variety of specifications) - sanding (removing burrs, etc.) - turning (mainly forming) - sanding the surface - engraving (such as knurling, printing LOGO, etc.) - heat treatment (in order to increase its hardness )--Electroplating (nickel or chrome, etc.)

Four distinctions between good and bad

(1) Look at the surface: Is there any burrs, whether the specifications meet the size standards, whether there are scratches, etc.

(2) Endoplasm: measuring torque and hardness with special tools; measuring size; salt spray test, etc.

Note: When the hexagonal or twelve-sided edge size of the socket wrench is less than or equal to 32MM, the hardness value is not lower than HRC39. When it is greater than 32MM, the hardness is not lower than HRC35.

About

Changzhou Cnpow Mechanical Technology Co., Ltd.is located in the heavy industrial city - Jiangsu Changzhou, the registered capital of 3 million yuan, covers an area of 30000 square meters, has more than 100 employees, ...

MOREProducts

Contact us

- Changzhou Cnpow Mechanical Technology Co., Ltd.

- Contacts: Ting .Tang

- Tel:0519-83819111

- Mobile:13775075252

- E-mail:zodojx@163.com

- ADD:Changzhou city Wujin District Hengshanqiao Town XiYancun Industrial Park